- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: Shandong, China

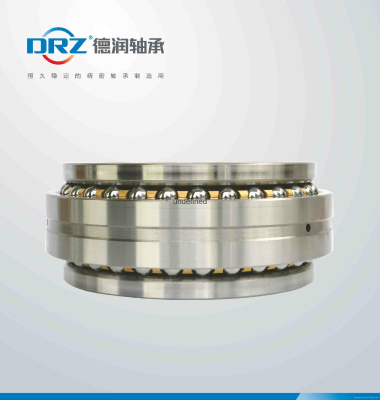

- Brand Name: DRZ

- Model Number: 2344/2347

Double-direction Angular Contact Thrust Ball Bearing

DRZ double direction angular contact thrust ball bearing is a bearing unit composed of an integral outer ring, a group of sectile inner rings, steel balls, cage assemblies and sealing. It features compact structure, small size and high rotating accuracy, enduring force in two directions and bearing certain axial load while holding very high radial load, and multiple structure styles, broad adaptability and easy installation. It is widely used in combination lathe or the spiral-rod drive in machining center.

Double direction thrust angular contact ball bearings have 60 ° contact angle, they are composed of a bearing seat with lubrication oil grooves and oil bore, two shafts, one spacer and two cages with many steel balls. The width of the spacer can guarantee bearings to attain pre-load assembly.

DRZ can provide high precision angular contact ball bearing with P6、P5、SP、UP class.

Types of Designs:

Angular contact ball, double channel outer rings and dissectible inner rings combine into one which can bear double direction load. Lip seal or gap seal can be adopted according to the circumstances.

Product Precision Accuracy:

Dimensional tolerance and geometrical accuracy is based on GB/T307P4.

Matched steel ball precision grade is Ⅲ (ISO GB/T308).

Materials:

Material for needle roller is GCr15 bearing steel, quench-hardening HRC60---65.

Material for inner and outer races is GCr15 bearing steel, quench-hardening HRC61---65.

Material for cages is reinforced nylon.

Precision class: P0,P6,P5,P4, UP

Size range: 10mm (bore diameter) to 1600mm

Contact angle: 60°

Special Directions:

Recommended tightening moment should be exerted during mounting so as to ensure its technical property.

Transmission must be carried out through bearing races when fitting.

Limited by plastic cages, grease and sealing material, operating temperature is not allowed to surpass 1200C during continuous work.

For optimum performance, machine tool spindle bearings must exhibit high rigidity as well as high precision, allowing only slight deflection under load.

Double direction angular contact thrust ball bearings achieve a very high level of rigidity through their internal design and preload.

Double direction angular contact thrust ball bearings series 2344-2347 should be used in combination with cylindrical roller bearings because they carry only thrust loads. Use of a cylindrical roller bearing in combination with a double row cylindrical roller bearing offers the advantage of supporting both axial and radial forces separately.

Double direction angular contact thrust ball bearings with 60° contact angle are well suited for applications requiring high axial stiffness.

They are manufactured to precision tolerances, and match the mounting dimensions of the NN30 Series double row cylindrical roller bearings. They feature a solid one piece brass cage which is ball guided.

Double direction angular contact thrust ball bearings can be lubricated with either grease or oil. The outer ring O.D. has a lubricating groove in the center with lubricating holes. The application of the lubricant between the two rows of balls allows optimal distribution of lubricant to both raceways.

Double direction angular contact thrust ball bearings are designed for use in machine tool spindles, in combination

with cylindrical roller bearings. They are manufactured to precision tolerances. Double direction angular contact thrust ball bearings are designed to carry only thrust loads.

They match the mounting dimensions of the NN30 Series double row cylindrical roller bearings which carry the bearing load.

Double direction angular contact thrust ball bearings are designed to be mounted in conjunction with a double row radial cylindrical roller bearing. The nominal size of the outside diameter is the same for both bearings which simplifies the machining of the housing bore. The outside diameter tolerance of the double direction angular contact thrust ball bearing is designed so that there is clearance between the bearing O.D. and the housing bore. Use of this bearing type, in combination with a double row

cylindrical roller bearing, offers the advantage of supporting both axial and radial forces separately.

Double direction angular contact thrust ball bearings have a contact angle of 60° and are axially preloaded. The contact angle and the axial preload ensures good ball control, especially under the centrifugal forces with fast rotating spindles.

These bearings are designed to accommodate high thrust loads. They have solid one piece machined brass cages which are ball guided.

Speed limit values for grease and oil lubrication are given in the bearing tables beginning on page 120.

Orientation of double direction angular contact thrust ball bearings of series 2344 and 2347 in relation to double row cylindrical roller bearings

Double direction angular contact thrust ball bearings can be lubricated with either grease or oil. The outer ring O.D. has a lubricating groove in the center with lubricating holes.The application of the lubricant between the two rows of balls allows optimal distribution of lubricant to both raceways.

For optimum performance, machine tool spindle bearings must exhibit high rigidity as well as high precision.

This means that they must run precisely and must allow only slight deflection under load. The double direction angular contact thrust ball bearings achieve high axial rigidity through their internal design with 60° contact angle and a defined heavy preload.

Lubrication

Angular contact thrust ball bearings can be either grease or oil lubricated. The housing washer design in the bearing features a lubrication groove and lubrication holes at the center.

The lubricant supply between the two rows of balls is rapidly dispersed by the centrifugal force of the bearing. For this reason double direction angular contact thrust ball bearings require a considerably greater amount of oil than an adjacent cylindrical roller bearing. At the design stage, attention should be paid to the fact that excess oil flow should not compromise the lesser lubrication requirements of cylindrical roller bearings.

- Place of Origin: Shandong, China

- Brand Name: DRZ

- Model Number: 2344/2347